YADBS - Stage 8

so next day we continue with the swingarm efforts. get a new bullet chain from JC road and we sit down to see how long a piece needs to be added. soon we find that we need 13 links extra and then the chain fits snugly. so thats done pretty soon and so at last the bike is now on a longer swingarm and sits 4 inches longer.

and hey where are the rear shocks and just what are those aluminum rods doing there? ok to answer that we must look into the "hardtail" story.

Hardtail setup

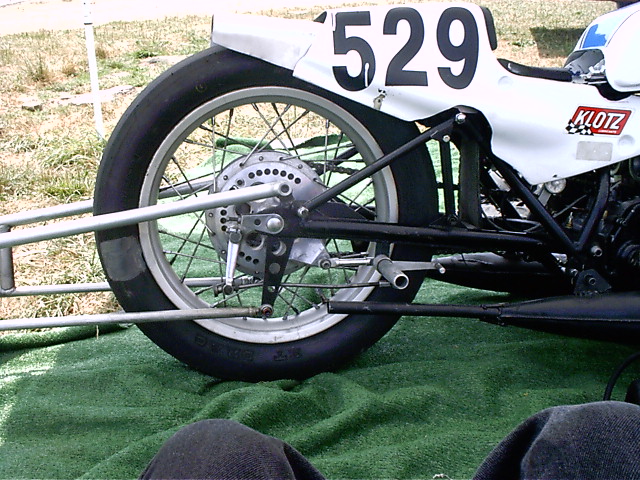

put simply, idea is to replace the rear shocks with aluminum struts. this is not something which we considered in our wildest dreams, actually. again credit goes to tom for this feature and im sure he would pass that onto a very nice guy - Tony Rovito - whom tom met in one of the bike forums out there. he helped us a lot, gave us a lot of tips, and this was one of them. Tony is in the US, and he drag races an RD. take a look at this pic and you would believe me when i tell you that he does low 12s and high 11s.

here is another shot of his bike.

it was from him that we get this idea, this idea of running struts instead of shocks. there are two distinct advantages here - one, weight reduction. and two, minimize chances of wheelspin and the power goes to the ground better.

in fact we combined this with the swingarm effort and thats when me and tom visit SJP road (near JC road) to check out some aluminium. soon we buy a piece of aluminum rod, around 1.5 inches thick. its long enough for two struts and the next step is to get them cut and milled. easier said than done, i hate that place. suffice to say that we walked around a good solid 3 hours in the sun, begging one machine shop guy after another to do the job for us. none of the guys seemed to be interested, and some quoted exorbitant charges hoping to scare us away. but when we agreed, he actually backed off, mumbling some lame reason like power failure or something like that. in the end we give up and head home. but by now, the pieces are cut and its the milling that needs to be done.

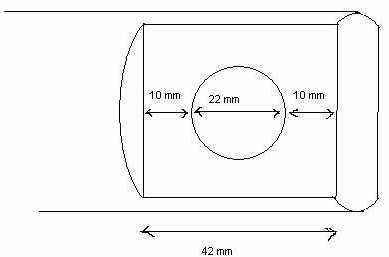

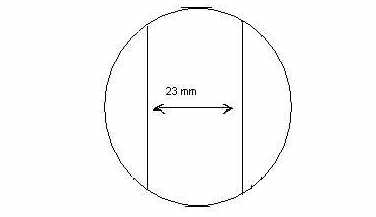

now tom has a friend, Rajesh, who owns a machine shop, and luckily he agrees to do it for us. so the pipes are off to rajeshs place, and this is what need to get done

this milling has to be done on both ends of both struts. the 22mm hole is into which the shock studs will go through, of course we plan to use the stock rubber washer as well. this is the "arial" view, or the view you get if you decide to poke yourself in the eye with one of the struts.

so its a matter of two days and the struts are back, beautifully milled. we hold them in place and it seem to fit fine.

you can see the chain lying on the floor - yes as i said earlier this adventure very much overlaps with the swingarm efforts and both happened within a period of three days. anyway now we have the swingarm in place, we have chain longer by 13 links and we have two milled struts and so its time to start assembling.